The Framers Language (Roof System)

With Roof Systems being as complicated as they are, any information provided needs to be clear and understandable. Not using complicated Architectural or Engineering terminology the Roof Framing Solutions method uses terms and phrases familiar with and used by Framing crews so there is a quick easy transfer and understanding of complicated Roof information. The Roof Framing Material Layout Plan, Roof System Rafter Cut List, and the Roof System Rafter Layout Plan are all written and laid out using the Framers Language. This is a language that Framers understand and use daily so there is no confusion or misunderstandings. With a quick review any Framing crew can read and understand all the information provided. Just straight Roof information we need written and laid out in a language we use.

Roof Framing Material List

After reviewing all the Architectural and Structural plans provided a complete Roof System Layout is developed with any recommendations needed for a Structurally Superior, Cost Effective, Brace Free Open Attic Roof System. Then a detailed material list is created listing all the material by Size, Length and Quantity to build the entire Roof System. This material list can be used for pre-construction material pricing and getting a firm cost for budgeting. Having Smarter Cost Control and Material Management for Roof construction will eliminate:

- Unexpected material over costs during construction

- Production loss during construction due to multiple orders and deliveries

- Costly waste piles and dump fees

- Stacks of overordered expensive material taking up valuable jobsite space

- Credit return issues

Roof Framing Material Layout Plan

The Material Layout Plan is a complete detailed Layout for a Brace Free Open Attic Roof System showing the Framer all the information needed to cut and set up the roof. With the Material Layout Plan there is no confusion as to what has been ordered and where it goes. There is no more guesswork on setting up the roof with detailed information such as the following:

- Material size, length and quantity ordered

- Material locations in the Roof System

- Layout starting point and directions

- All Vault Wall heights and locations

- All Roof knee wall Heights and Locations

- Al Roof kneewall setbacks for Switch Pitch Roofs

- All double Roof kneewall heights and locations

- Scaffold heights and locations

- Gable end overhangs for kneewalls

- Any Roof beam locations and heights

- Any specific or general information needed per Roof Section

Roof System Rafter Cut List

The Rafter Cut List provided to the Framer are cut sheets with specific detailed information, written in the Framer’s Language, needed to lay out, cu,t and number each rafter for the entire Roof Syste,m including the following:

Girder Rafters

Common Rafters

- Jack Rafters

- Valley Rafters

- Hips

- Fly Hips

- Valleys

- Valley Pads

- Ridges

- All Rafter and Hip Tails

- Radius Tails

- Radius roofs

With the Roof Framing Solutions Rafter Cut List the entire Roof System can be pre-cut, organized and stacked, ready to be assembled while the house is being framed, eliminating the loss of production with today’s slow, outdated stick framing methods or the problems with Prefab Roof Truss Systems.

Roof System Rafter Layout Plan

- Roof Sections

- Girder Rafters

- Rafter Sets

- Jack Rafter Sets

- Valley Jack Rafter Sets

- Load bearing Rafters for Secondary Roofs / False Dormers

- Load bearing Rafters for brick / stone

- Ridges

- Mid span Ridges

- Hangers / Bolts

- Dormers

- Head outs for Skylights or Masonry Chimneys

With the Roof Framing Solutions Roof System Rafter Layout Plan the entire Pre-cut Roof System can be moved into the correct location without any confusion and be ready to be assembled

Shotgun Takeoff

House Framing Materials List

After a review of all the architectural and structural plans provided, a complete structural layout is developed, along with any recommendations needed to build a cost-effective, structurally superior house. Then, a detailed Material List is created per level, listing all the Framing Material needed by Size, Length, and Quantity. This Material List can be used for Pre-construction pricing and getting a firm cost for budgeting. Having Smarter Cost Control and Material Management is critical to House construction and will eliminate:

- Unexpected Material costs during construction

- Production Loss during construction due to multiple orders and deliveries

- Costly Waste Piles and Dump Fees

- Stacks of Expensive Over-ordered Framing Lumber waiting to be returned taking up valuable jobsite space

- Credit Return Issues

House Framing Material Layout Plan

The House Framing Material Layout Plan, laid out in the Framers Language, is a complete detailed Layout of the Framing Material showing the Framer what has been ordered by Size, Length, Quantity and its Location. With the House Framing Material Layout Plan there is no more confusion regarding what has been ordered and where it goes, and the Framer can also use the Layout plan to double-check if the delivery is filled and then schedule the next Pre- stocked Package delivery. This helps create Smarter Cost Control and Material Management and eliminates:

- Shotgun Takeoffs

- Unnecessary Waste and Credit Return Issues

- Loss of Production Waiting on Material Deliveries

- Material misuse from confusion about orders

- Detailed Material List per Level

- Layout starting point and direction

- Specific Structural Components size and location

- Point Loads

- All General or Specific Structural Information needed per Level

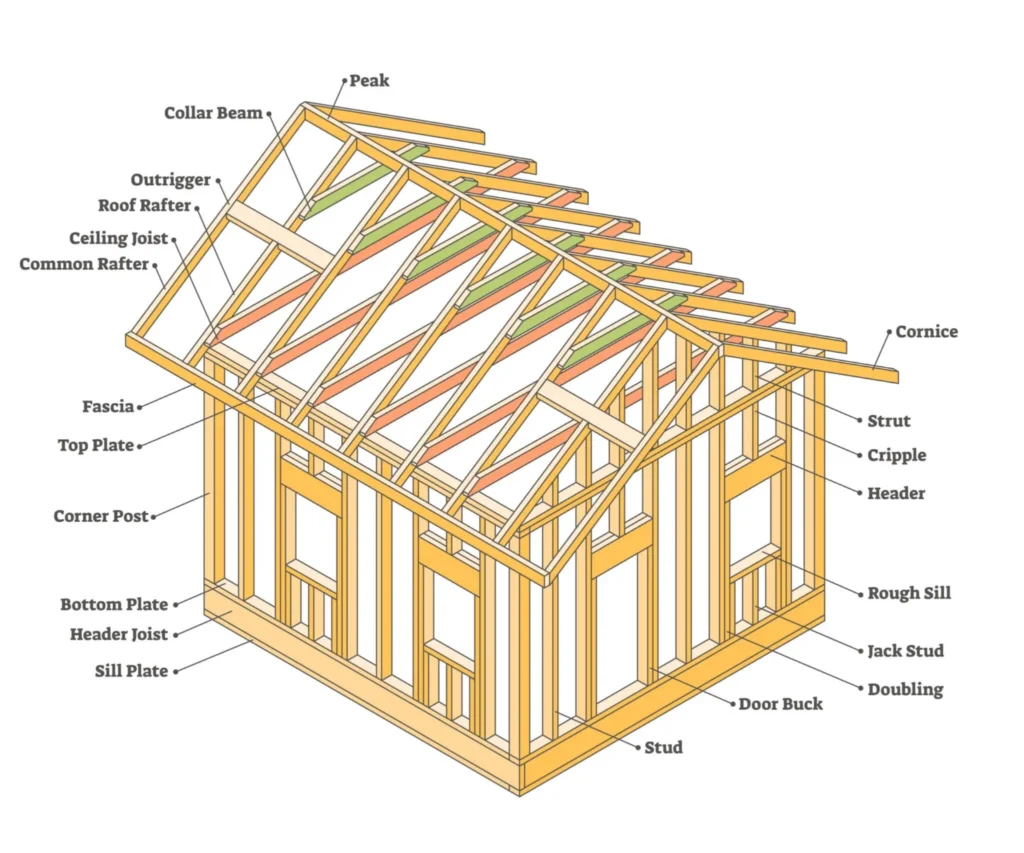

The Framers Language (House Systems)

With the complicated Structural Layout of a house the information needed by the Framer needs to be direct and specific to build a structurally correct house. Not using complicated Architectural and Engineering terminology the House Framing Solutions method uses The Framers Language. These are terms and phrases used by Framing crews so there is no confusion in the transfer of information. The House Framing Material Layout Plan and Material List are all laid out and written in the Framers Language and with a quick review any Framing crew can read and understand all the information provided. Just straight Build information we need written and laid out in the Language we use.